Gate Drive for step-down switching regulator

CDV/DT INDUCED TURN-ON IN SYNCHRONOUS BUCK

REGULATORS

Abstract

Cdv/dt induced turn-on of the synchronous MOSFET deteriorates

performance in synchronous buck regulators. We will discuss this

problem and provide several solutions that can reduce the effects.

BIPOLAR OR CMOS GATE DRIVER?

An in-circuit waveform showing the Cdv/dt induced

turn-on effect at Q2 gate is demonstrated in Figure 7. The

gate drive circuit might further deteriorate this Cdv/dt

induced turn-on problem. It is clear in Figure 7 that the

gate driver can only pull the gate voltage of Q2 down to

0.7V, instead of zero, when Q2 is turned off. However, the

Cdv/dt induced voltage is sitting on top of this turn-off

gate voltage and makes Q2 more vulnerable to the Cdv/dt

induced turn-on problem. The gate driver used in Figure 7

is created by a bipolar process.

http://www.irf.com/technical-info/whitepaper/syncbuckturnon.pdf

“Shoot-through” in Synchronous Buck Converters

Abstract

The synchronous buck circuit is in widespread use to

provide “point of use” high current, low voltage

power for CPU’s, chipsets, peripherals etc. In the

synchronous buck converter, the power stage has a

“high-side” (Q1 below) MOSFET to charge the

inductor, and a “Low-side” MOSFET which replaces

a conventional buck regulator’s “catch diode” to

provide a low-loss recirculation path for the inductor

current.

“Shoot-through” in Synchronous Buck Converters

Abstract

The synchronous buck circuit is in widespread use to

provide “point of use” high current, low voltage

power for CPU’s, chipsets, peripherals etc. In the

synchronous buck converter, the power stage has a

“high-side” (Q1 below) MOSFET to charge the

inductor, and a “Low-side” MOSFET which replaces

a conventional buck regulator’s “catch diode” to

provide a low-loss recirculation path for the inductor

current.

Shoot-through is defined as the condition when both

MOSFETs are either fully or partially turned on,

providing a path for current to “shoot through” from

VIN to GND. To minimize shoot-through,

synchronous buck regulator IC’s employ one of two

techniques to ensure “break before make” operation

of Q1 and Q2 to minimize shoot-through:

1. Fixed “dead-time”: A MOSFET is turned off,

then a fixed delay is provided before the lowside

is turned on. This circuit is simple and

usually effective, but suffers from its lack of

flexibility if a wide range of MOSFET gate

capacitances are to be used with a given

controller. Too long a dead-time means high

conduction losses. Too short a dead time can

cause shoot-through. A fixed dead-time

typically must err on the “too long” side to allow

high CGS MOSFETs to fully discharge before

turning on the complementary MOSFET.

2. Adaptive gate drive: This circuit looks at the

VGS of the MOSFET that’s being driven off to

determine when to turn on the complementary

MOSFET. Theoretically, adaptive gate drives

produce the shortest possible dead-time for a

given MOSFET without producing shootthrough.

In practice, a combination of adaptive and fixed

produces the best results, and is typically what is in

today’s PWM controllers and gate drivers as shown

in Figure 2

MOSFETs are either fully or partially turned on,

providing a path for current to “shoot through” from

VIN to GND. To minimize shoot-through,

synchronous buck regulator IC’s employ one of two

techniques to ensure “break before make” operation

of Q1 and Q2 to minimize shoot-through:

1. Fixed “dead-time”: A MOSFET is turned off,

then a fixed delay is provided before the lowside

is turned on. This circuit is simple and

usually effective, but suffers from its lack of

flexibility if a wide range of MOSFET gate

capacitances are to be used with a given

controller. Too long a dead-time means high

conduction losses. Too short a dead time can

cause shoot-through. A fixed dead-time

typically must err on the “too long” side to allow

high CGS MOSFETs to fully discharge before

turning on the complementary MOSFET.

2. Adaptive gate drive: This circuit looks at the

VGS of the MOSFET that’s being driven off to

determine when to turn on the complementary

MOSFET. Theoretically, adaptive gate drives

produce the shortest possible dead-time for a

given MOSFET without producing shootthrough.

In practice, a combination of adaptive and fixed

produces the best results, and is typically what is in

today’s PWM controllers and gate drivers as shown

in Figure 2

http://www.fairchildsemi.com/an/AN/AN-6003.pdf

A New Hybrid Gate Drive Scheme for High

Frequency Buck Voltage Regulators

Abstract

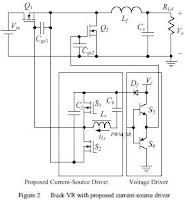

This paper presents a new hybrid drive scheme

for a synchronous buck voltage regulator (VR). The

proposed current-source driver is used to drive the control

MOSFET to achieve fast switching speed and reduce the

switching loss significantly due to the parasitic inductance in

addition to gate energy recovery. Conventional voltage

driver is used for synchronous rectifier (SR) MOSFET for

its simplicity and good immunity and alleviation of dv/dt

effect. The experimental results prove the advantages of the

new drive scheme and a significant efficiency improvement

has been achieved. At 1.3 V output, the new driver improves

the efficiency from 82.8% using a conventional driver to

85.6% (an improvement of 2.8%) at 20 A, and at 25 A, from

80.5% to 83.0% (an improvement of 2.5%). The new drive

can also be integrated into a standard drive integrated

circuit (IC) and replace the conventional voltage drive IC

directly. Overall, the new driver scheme is very promising

from the standpoints of both performance and costeffectiveness.

Figure 2 shows the buck converter with the proposed

hybrid drive circuit. The key waveforms are shown in

Figure 3. Essentially, the new high-side current-source

driver is used for the control MOSFET to achieve fast

switching transition. It consists of two driver MOSFETs

S1 and S2, a bipolar transistor pair S3 and S4, the resonant

inductor Lr, the bootstrap capacitor Cf , diode Df and the

blocking capacitor Cb. Vc are the drive voltages. Cgs1 and

Cgs2 are the input gate capacitors of MOSFETs Q1 and Q2

respectively. S1 and S2 are switched out of phase with

complimentary control respectively.

A New Hybrid Gate Drive Scheme for High

Frequency Buck Voltage Regulators

Abstract

This paper presents a new hybrid drive scheme

for a synchronous buck voltage regulator (VR). The

proposed current-source driver is used to drive the control

MOSFET to achieve fast switching speed and reduce the

switching loss significantly due to the parasitic inductance in

addition to gate energy recovery. Conventional voltage

driver is used for synchronous rectifier (SR) MOSFET for

its simplicity and good immunity and alleviation of dv/dt

effect. The experimental results prove the advantages of the

new drive scheme and a significant efficiency improvement

has been achieved. At 1.3 V output, the new driver improves

the efficiency from 82.8% using a conventional driver to

85.6% (an improvement of 2.8%) at 20 A, and at 25 A, from

80.5% to 83.0% (an improvement of 2.5%). The new drive

can also be integrated into a standard drive integrated

circuit (IC) and replace the conventional voltage drive IC

directly. Overall, the new driver scheme is very promising

from the standpoints of both performance and costeffectiveness.

Figure 2 shows the buck converter with the proposed

hybrid drive circuit. The key waveforms are shown in

Figure 3. Essentially, the new high-side current-source

driver is used for the control MOSFET to achieve fast

switching transition. It consists of two driver MOSFETs

S1 and S2, a bipolar transistor pair S3 and S4, the resonant

inductor Lr, the bootstrap capacitor Cf , diode Df and the

blocking capacitor Cb. Vc are the drive voltages. Cgs1 and

Cgs2 are the input gate capacitors of MOSFETs Q1 and Q2

respectively. S1 and S2 are switched out of phase with

complimentary control respectively.

Labels: buck, Gate Drive, step-down switching regulator

<< Home